Hot end spare parts

Clicking the underlined text or the picture leads to additional information

Please contact us in case you require parts which are not in the list.

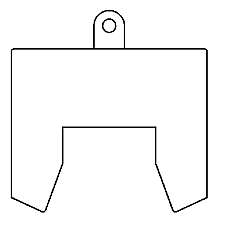

Widths 80 ... 240mm

Shapes: Bottles (standard) - Wide mouth, Jar - Short neck

For easy adjustment and job change

With the brackets the hood opens/closes side ways

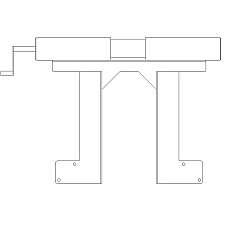

The finish blower drives clean air into the mid section

to keep the mouth of the container free from coating

The circulation blowers drive the coating gasses through the coating hood

Wheel diameters 135mm, 160mm or 170mm

Two cooling blowers (one at each side of the hood) drive "cool" air from beneath through the radiator of the hood.

Complete set

Available in: 230V and 400V, 750W and 2500W

230V - 400V

750Watt - 2500Watt

The Exhaust blower creates an under pressure in the exhaust system to extract unused coating gasses.

Sensor to detect the presence of glass

With the signal of this sensor the pump can be started/stopped

A 0-100 kg weighing scale shows the contents of the chemicals in the drum

The Load cell transmits the weight of the drum (content) to a PLC

Especially for MBTC (hot end coating chemicals)

Solenoid - Diaphragm

Several brands and types available

MBTC resistant connection parts, such as:

PVDF tubing

PVDF connectors

Brass connectors

With a flow meter the correct flow of chemical transfer to the coating hood.can be detected

The equipment can be supplied with or without detection sensors.

Installation parts

To guide the PVDF suction line into the drum a ceramic foot valve can be connected.

The specially designed (bubble free) suction lance guarantees trouble free changing of the drum.

DinterS BV

René van den Dorpel

T: +31 (0) 625385722

E: info@dintersindustrial.nl

VAT: NL861796469B01

.png?width=225%&height=auto&quality=60&cropratio=1:1&image=/uploads/galleries%2FHot+end+coating%2FPicture+available+soon%281%29.png)

.JPG.jpg?width=225%&height=auto&quality=60&cropratio=1:1&image=/uploads/galleries%2FHot+end+coating%2FHot+end+coating+Flow+meter+Type+A%282%29.JPG.jpg)

.jpg?width=225%&height=auto&quality=60&cropratio=1:1&image=/uploads/galleries%2FHot+end+coating%2Fhot+end+coating+foot+valve+1%281%29.jpg)